Industrial Cooling and Heating System

Industrial Cooling and Heating System Specification

- Product Type

- Industrial use

- Material

- Stainless Steel

- Type

- Food Dryer, Food Processors, Snacks Extruder

- Product Shape

- Other

- Computerized

- No

- Automatic

- No

- Control System

- Manual

- Installation Type

- Free Stand

- Voltage

- 220 Volt (v)

- Power

- 10000 Watt (w)

- Dimension (L*W*H)

- 1250*2500 Millimeter (mm)

- Feature

- Lower Energy Consumption, ECO Friendly, Low Noice, Compact Structure, High Efficiency

- Color

- Black

- Warranty

- 12month

Industrial Cooling and Heating System Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash on Delivery (COD), Delivery Point (DP), Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T), Cash Against Delivery (CAD), Days after Acceptance (DA), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 100 Pieces Per Week

- Delivery Time

- 1 Week

- Main Export Market(s)

- Central America, Australia, North America, Eastern Europe, South America, Western Europe, Middle East, Asia, Africa

- Main Domestic Market

- All India

About Industrial Cooling and Heating System

A complete HVAC (Heating, Ventilation, and Air Conditioning) system called an industrial cooling and heating system is created to effectively control temperature in sizable industrial or commercial buildings. To keep a cosy and controlled environment, it combines cooling and heating capabilities.

The following are the characteristics and parts that are frequently found in an industrial cooling and heating system:

1. Cooling Components: To cool the area, the system uses cooling components like chillers, cooling towers, or air conditioners that remove heat from the air or water. Depending on the particular needs of the facility, these components may be cooled by air or by water.

2. Heating Components: To supply heat during the winter months, the system incorporates heating elements, boilers, or heat pumps. To increase the temperature in the area, they produce warm air or water.

3. Air Distribution System: A system of ducts and vents guarantees that conditioned air is distributed properly throughout the building. It maintains a constant temperature while delivering cooled or heated air to the desired locations.

4. Advanced controllers and sensors are built into the system to keep track of environmental variables including humidity levels and temperature. This makes it possible to precisely and automatically control the cooling and heating processes.

5. Insulation and thermal barriers are used in the design of industrial cooling and heating systems to reduce heat transfer and increase energy efficiency. By doing so, energy consumption is decreased and the desired temperature levels are maintained.

6. Energy Recovery: To capture and repurpose waste heat from the cooling process, some systems integrate energy recovery components, such as heat exchangers. This encourages energy conservation and lowers operational expenses.

7. Ventilation and Air Filtration: The system incorporates air filtration machines to guarantee proper ventilation and fresh air exchange. These systems clean and filter the incoming air, eliminating impurities and preserving good indoor air quality.

8. Zoning and individual control: Industrial cooling and heating systems may have the ability to zone, allowing for independent control of various sections or zones inside the facility. This makes it possible to create specific temperature controls based on requirements and occupancy levels.

9. Monitoring and upkeep: The system may be equipped with remote monitoring features that provide real-time information on system performance, energy usage, and potential problems. Regular servicing and maintenance promote long-term system performance.

An industrial cooling and heating system has the following advantages:

1. Temperature Control: The system maintains a cosy and controlled atmosphere by supplying heating during colder months and cooling during hotter months.

2. Advanced controls, energy recovery systems, and optimised system design all help to increase energy efficiency, which lowers running costs and has a less negative impact on the environment.

3. A healthier and more productive work environment is produced by proper ventilation, air filtration, and humidity control, which also improve indoor air quality.

4. Flexibility and Zoning: Zoning features enable individualised temperature management in various areas, optimising comfort and energy consumption depending on particular needs.

5. Reliability and Durability: Industrial cooling and heating systems are made to resist rigorous industrial environments and heavy usage, ensuring dependable operation and durability.

6. Maintaining temperate temperatures encourages a comfortable and productive work environment for employees, which increases productivity and output.

7. Safety and Compliance: Industrial cooling and heating systems are made to adhere to safety norms and legal regulations, creating a compliant and secure working environment.

An industrial cooling and heating system offers comfortable, energy-efficient, and better indoor air quality temperature control for large industrial or commercial buildings. It increases productivity, guarantees adherence to rules, and gives workers a pleasant place to work.

Product Details

|

Type Of Freezer |

Top Freezer |

|

Door Type |

Double Door |

|

Door Material |

Stainless Steel |

|

Brand |

Steel Craft |

|

Body Material |

Stainless Steel |

|

Power Source |

Electricity |

Efficient, Eco-Friendly Performance

The system ensures high drying and processing efficiency while maintaining lower energy consumption and minimal noise levels. Its eco-friendly features make it a sustainable solution for modern food industries, reducing operational costs and environmental impact.

Robust Stainless Steel Build

Manufactured with high-grade stainless steel, this unit guarantees durability and longevity. The corrosion-resistant structure ensures safe operation under demanding industrial conditions, with easy maintenance and extended product lifespan.

Simple Manual Control and Maintenance

With its manual control system, this equipment eliminates the need for computerized components, allowing straightforward daily use and adjustment. Maintenance becomes easier, making it suitable for factories seeking reliable performance without complex systems.

FAQ's of Industrial Cooling and Heating System:

Q: How is the Industrial Cooling and Heating System operated without computerized controls?

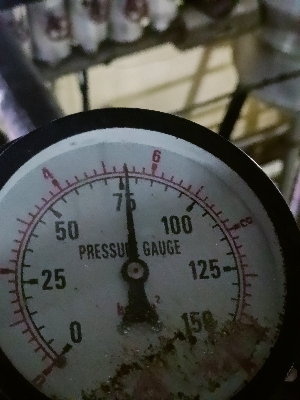

A: This system employs manual controls, enabling operators to adjust settings directly through physical switches and dials. It provides reliable, straightforward usage without relying on computerized panels, simplifying both operation and troubleshooting.Q: What are the key benefits of using this stainless steel food processor in my facility?

A: Utilizing premium stainless steel, the processor delivers high efficiency and durability with lowered energy use, eco-friendly operation, and low noise output. Its compact structure allows for easy placement and integration into your production line.Q: Where can the system be effectively installed within an industrial setting?

A: As a free-standing unit, the system can be placed in any production area with adequate space for its dimensions (1250*2500 mm) and a 220-volt power connection. Its design supports flexible installation in various food processing environments.Q: What is the typical process for food drying or extrusion using this machine?

A: Operators load food material into the unit, make precise manual adjustments for temperature and airflow, and begin the cycle. The system's robust heating and cooling mechanism ensures even processing, delivering consistent results for drying or extrusion tasks.Q: When is routine maintenance recommended to ensure optimal performance?

A: Regular maintenance, such as inspection, cleaning, and routine checks on moving parts, should be carried out every few months. The simplicity of manual controls and stainless steel construction makes maintenance straightforward, reducing downtime.Q: How does the system support environmentally conscious production?

A: The machine's eco-friendly technology is engineered to minimize energy consumption and noise while maintaining high processing efficiency, thus helping your facility meet sustainable operation goals.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Steam Boiling Tanks Category

Boiling Kettle

Price 50000.00 INR / Piece

Minimum Order Quantity : 1 Number

Warranty : 12 month

Material : Stainless Steel

General Use : Process industry

Weight (kg) : 100kg Kilograms (kg)

Syrup Preparation Vat

Price 50000.00 INR / Piece

Minimum Order Quantity : 1 Number

Warranty : 12month

Material : Stainless Steel

General Use : Food industry

Weight (kg) : 50 kg Kilograms (kg)

Screw Conveyor

Price 50000 INR / Unit

Minimum Order Quantity : 1 Meter

Warranty : 12 month

Material : Stainless Steel

General Use : For material transfer

Weight (kg) : 75 Kilograms (kg)

Conical Vat

Price 25000.00 INR / Piece

Minimum Order Quantity : 1 Number

Warranty : 12 month

Material : Stainless Steel

General Use : For use in Pharma industries,dairy industries, bakery,chemical industries,honey processing industries,hurbal processing industries etc

Weight (kg) : 130 kg Kilograms (kg)

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free