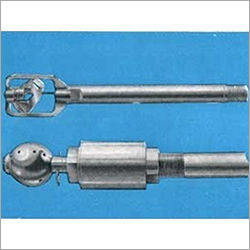

Tank Cleaning Equipment

Tank Cleaning Equipment Specification

- Usage

- Industrial

- Material

- SS

- Condition

- New

- Fuel Type

- Electric

- Product Type

- Tank Cleaning Equipment

- Color

- Sliver

Tank Cleaning Equipment Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Week

- Delivery Time

- 1 Week

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Tank Cleaning Equipment

The high-pressure water jets of automated tank cleaning machines, tank sprayers for focused cleaning, tank brushes for hand scrubbing, CIP systems for automatic cleaning, and tank inspection cameras for visual inspections are just a few of the tank cleaning tools available. These tools effectively clean deposits, pollutants, and residue from tank surfaces. Benefits include increased cleaning effectiveness, cost savings, increased safety, regulatory compliance, increased equipment longevity, and adaptability to different tank sizes and industries. Industries that use tanks for storage, processing, and transportation need tank cleaning equipment to maintain cleanliness, hygiene, and operational effectiveness.

Here are a few typical types of tank cleaning tools:

1. Tank cleaning machines: Tank cleaning machines are automated equipment that spray cleaning ingredients and water onto the surface of tanks to remove pollutants and tenacious residues. These devices can be remotely controlled or installed on tank walls.

2. Sprayers for tanks: Sprayers for tanks are handheld or portable devices used to spray cleaning chemicals, solvents, or sanitising solutions within tanks. They frequently have nozzles or spray patterns that may be adjusted for effective coverage and cleaning that is focused.

3. Tank brushes are hand-held cleaning instruments with long handles and firm bristles. To remove debris, leftovers, and scale from tank surfaces, they are used to scrape and agitate the surfaces. To accommodate differing tank diameters and cleaning needs, tank brushes are available in a variety of sizes and configurations.

4. Tank CIP Systems: CIP (Clean-In-Place) systems are automated systems that clean tanks without the need for disassembly by using a combination of cleaning chemicals, heat, and circulation. Pumps, valves, and spray balls are commonly used in these systems to distribute cleaning agents throughout the tank.

5. Borescopes or tank inspection cameras are used to visually inspect the interior of tanks for imperfections, scuffs, or other problems. These cameras are mounted on pliable probes that can be inserted through access ports into the tank.

Tank cleaning equipment advantages:

1. Efficiency: Tank cleaning technology makes it possible to clean tanks thoroughly and efficiently, which cuts down on the time and labour needed to manually clean tanks.

2. Cost Savings: Automated tank cleaning technology can save money by cutting labour expenses and lowering downtime while tank cleaning and maintenance procedures are being carried out.

3. Safety: The use of tank cleaning equipment lessens the need for employees to access tight spaces or work in dangerous conditions, improving employee safety and lowering the dangers involved with manual cleaning.

4. Tank cleaning equipment uses standardised procedures and techniques to achieve consistent cleaning outcomes, which lowers variability and increases cleanliness.

5. Compliance: In sectors including food and beverage, pharmaceuticals, and chemical processing, regulatory compliance depends on proper tank cleaning. Equipment for tank cleaning aids in maintaining safety and hygienic requirements.

6. Increases Equipment Lifespan: By preventing corrosion, accumulation, and contamination, regular tank cleaning with the right tools can increase the lifespan of tanks and related equipment.

7. Flexibility: Tank cleaning equipment can be configured in a number of ways to fit varied tank types, shapes, and cleaning needs, providing versatility across a range of industries and applications.

In sectors that rely on tanks for storage, processing, and transportation, tank cleaning equipment is essential to preserving cleanliness, hygiene, and operating efficiency. These tools guarantee thorough cleaning, lower labour costs, increase safety, and encourage regulatory compliance.

Sturdy Stainless Steel Construction

Built with robust stainless steel, our tank cleaning equipment resists corrosion and offers long-lasting durability, essential for industrial environments. The silver finish adds aesthetic appeal while ensuring easy maintenance. This high-quality material contributes to the equipment's ability to withstand continuous and rigorous use.

High-Performance Electric Operation

This equipment is powered electrically, delivering consistent and uniform cleaning results. Electric operation eliminates the need for manual labor, boosting productivity and reducing operational costs. Its advanced motor ensures reliable and efficient tank cleaning for various industrial sectors.

Industry-Leading Expertise

As a manufacturer, exporter, supplier, and service provider in India, we offer comprehensive support and global distribution. Our team possesses extensive industry knowledge, ensuring that each product meets stringent quality standards and specific client requirements for industrial tank maintenance.

FAQ's of Tank Cleaning Equipment:

Q: How is the tank cleaning equipment utilized in industrial settings?

A: The tank cleaning equipment is designed for use in large-scale industrial facilities, efficiently cleaning tanks through automated electric operation. Simply position the equipment inside the tank, connect to a power source, and initiate the cleaning cycle as per your requirements.Q: What is the primary material of construction for this equipment?

A: This equipment is constructed from high-quality stainless steel (SS), ensuring corrosion resistance and strength for demanding industrial applications.Q: When should tank cleaning equipment be serviced or maintained?

A: Regular maintenance should be scheduled based on usage frequency and tank contents. Typically, periodic inspections and routine servicing are recommended to ensure optimal performance and longevity.Q: Where is this equipment manufactured and available for export?

A: All equipment is manufactured in India. We leverage our export network to supply to various countries, ensuring prompt and reliable delivery to clients worldwide.Q: What is the process for cleaning a tank with this electric equipment?

A: The cleaning process involves positioning the equipment within the tank, connecting it to a reliable power source, and activating its electric cleaning features. The automated system delivers thorough cleaning and sanitation with minimal human intervention required.Q: Why choose electric tank cleaning equipment over manual methods?

A: Electric tank cleaning equipment delivers quicker and more thorough results, enhances safety for operators, reduces manual labor, and improves overall productivity in industrial cleaning applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cleaning Equipment Category

Vegetable Washing Machine

Price 50000.00 INR / Unit

Minimum Order Quantity : 1 Number

Fuel Type : Other

Length : 500mm Millimeter (mm)

Color : Stainless Steel

Product Type : Cleaning equipment for vegetables

Send Inquiry

Send Inquiry Send SMS

Send SMS