Vegetable Washing Machine

Vegetable Washing Machine Specification

- Material

- Metal

- Usage

- For commercial kitchen

- Type

- Other

- Size

- 500*500*1000mm

- Fuel Type

- Other

- Height

- 1000mm Millimeter (mm)

- Product Type

- Cleaning equipment for vegetables

- Cleaning Process

- Cold Water Cleaning

- Weight

- 40 Kilograms (kg)

- Cleaning Type

- High Pressure Cleaner

- Color

- Stainless Steel

- Length

- 500mm Millimeter (mm)

- Capacity

- 100 kg Kg/day

- Width

- 500mm Millimeter (mm)

- Voltage

- 220 Volt (v)

Vegetable Washing Machine Trade Information

- Minimum Order Quantity

- 1 Number

- Payment Terms

- Cash Against Delivery (CAD), Cash on Delivery (COD), Cash Advance (CA), Cash in Advance (CID), Cheque, Days after Acceptance (DA), Delivery Point (DP), Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T), Western Union, Letter of Credit (L/C)

- Supply Ability

- 1 Number Per Week

- Delivery Time

- 10 Days

- Sample Policy

- Free samples available with shipping and taxes paid by the buyer

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Vegetable Washing Machine

A specialised instrument called a vegetable washing machine is used in the food sector to effectively clean and sanitise fruits and vegetables. It has a revolving drum or conveyor for gentle cleaning, a water spraying system with adjustable flow and pressure, and optional air drying mechanisms. It is made of food-grade materials. These devices offer complete cleaning, clearing veggies' surfaces of debris, soil, pesticides, and pollutants. They ensure consistent cleaning outcomes, reduce labour costs, and advance food safety. Vegetable washing machines are crucial for effective and hygienic vegetable preparation in commercial kitchens, food processing facilities, and other food-related businesses because of their configurable features, hygienic design, and ease of maintenance.

The following are some characteristics and advantages of a vegetable washing machine:

Features of Vegetable Washing Machine:

1. Construction: To ensure longevity, hygiene, and corrosion resistance, vegetable washing machines are often built from stainless steel or other food-grade materials.

2. These machines have a water spraying system with nozzles that are placed strategically to clean veggies by spraying water at high pressure.

3. Water flow and pressure adjustments are possible with vegetable washing machines, allowing for customisation based on the type of vegetables being cleaned and the desired level of cleaning.

4. Rotating Drum or Conveyor: Some machines incorporate rotating drums or conveyor belt systems that transport and gently tumble the veggies through the washing procedure, providing thorough cleaning.

5. Filtration system: Some machines have a filtration system to keep the washing solution clean by removing dirt, debris, and contaminants from the washing water.

6. Variable Speed Control: Modern vegetable washing machines have this feature, which enables operators to alter the conveyor or drum's rotation speed to best suit the cleaning needs of various vegetable species.

7. In order to help with the preservation and packaging procedures, some machines have air drying or spin drying mechanisms that remove any surplus moisture from the washed vegetables.

Benefits of Vegetable Washing Machine:

1.Effective Cleaning: Vegetable washing machines efficiently and thoroughly clean vegetables by eliminating any pollutants that may be present on the surface, including dirt, soil, pesticides, and stains.

2. Savings in time and labour are made possible by the automation of the washing process, which eliminates the need for manual labour in food processing activities.

3. Results in Cleaning That Are Consistent: The machines' standardised water flow, pressure, and rotation speed guarantee results in Cleaning That Are Consistent, Increasing Food Safety and Product Quality.

4. Sanitary and hygienic: Vegetable washing machines are made to adhere to high standards of sanitation, guaranteeing that the vegetables are fully washed and sanitised, hence reducing the danger of foodborne infections.

5. Versatile Application: These machines are capable of processing a wide range of fruits and vegetables, including leafy greens, delicate fruits, and root vegetables.

6. Water Conservation: Vegetable washing machines frequently include water filtration and recycling technologies, which lower water usage and support sustainable food production methods.

7. Ease of Maintenance: Vegetable washing machines are built with characteristics like removable parts and simple access to the washing chamber that make cleaning and maintenance quick and simple.

In order to ensure food safety and quality throughout food processing activities, a vegetable washing machine delivers effective, automated, and hygienic cleaning of vegetables and fruits. Commercial kitchens, food processing plants, and other food-related sectors depend on it because of its adaptable characteristics, low maintenance requirements, and time-saving capabilities.

High-Efficiency Cleaning for Commercial Use

Engineered for commercial kitchens, the machine delivers thorough cleaning using cold water and high pressure. Its stainless steel build ensures longevity, while the compact size maximizes utility in busy food service environments. Capable of handling up to 100 kg per day, this washer streamlines your operations and maintains hygiene standards effortlessly.

User-Friendly Operation and Maintenance

Designed with practicality in mind, the washing machine features straightforward controls, facilitating easy operation for staff. Maintenance is hassle-free due to its accessible build and robust metal structure, guaranteeing reliable service. The stainless steel finish not only adds durability but also simplifies regular upkeep.

FAQ's of Vegetable Washing Machine:

Q: How does the vegetable washing machine clean produce?

A: The machine utilizes high-pressure cold water jets to thoroughly wash and remove dirt, pesticides, and contaminants from vegetables. The efficient process ensures all produce is cleaned safely without damaging delicate items.Q: What types of kitchens are best served by this washing machine?

A: This machine is ideally suited for commercial kitchens including restaurants, catering businesses, and food processing facilities that require large-scale, rapid, and sanitary washing of vegetables every day.Q: When should I use the machine during food preparation?

A: It's recommended to use the washing machine at the initial stage of food prep, immediately after vegetables are received and before they go into further processing or cooking, for optimal hygiene.Q: Where can this vegetable washing machine be installed?

A: The compact 500x500x1000 mm dimensions allow flexible installation in commercial kitchen spaces. It's designed for indoor, level surfaces with easy access to a 220V power outlet.Q: What is the cleaning process involved?

A: Vegetables are placed inside the stainless steel chamber, where high-pressure cold water jets target and remove impurities from all surfaces. This thorough approach ensures consistent cleanliness every cycle.Q: How do I benefit from using this machine?

A: The machine saves labor, improves hygiene, and offers uniform cleaning compared to manual washing. It is highly durable, reduces water usage, and increases productivity for large volumes of vegetables daily.Q: What maintenance is required to keep the machine operational?

A: Regularly check and clean the water nozzles, wipe down the stainless steel surfaces, and ensure the drainage system is clear. Periodic inspections of electrical connections help maintain safety and performance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cleaning Equipment Category

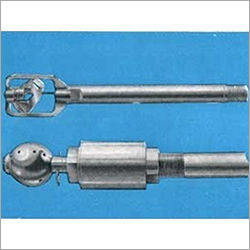

Tank Cleaning Equipment

Price 10000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Condition : New

Usage : Industrial

Fuel Type : Electric

Color : Sliver

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free